The Automotive division of Pneumax designs and manufactures a complete range of products dedicated to the production lines of the automotive field, focusing on Body in White applications.

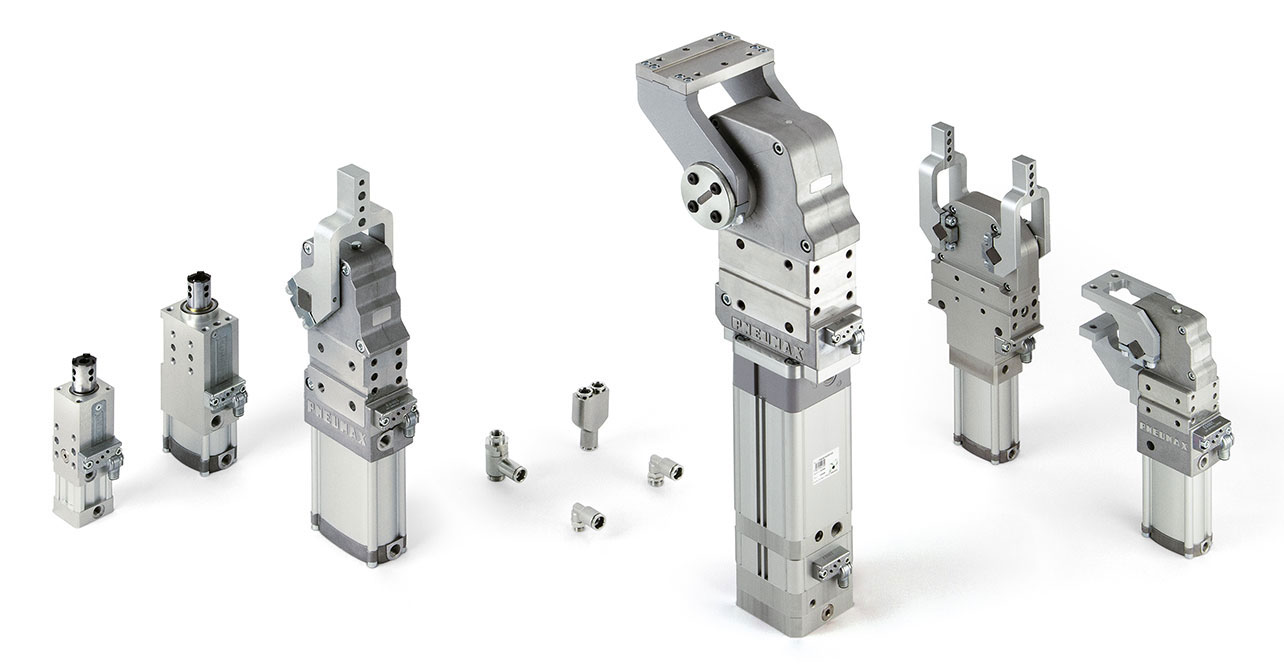

Pneumax offers a comprehensive range of clamping units, pivot units, pin packages as well as grippers and complete multi-axis positioning systems. Developed by a team of specialized technicians, the product is designed to ensure maximum reliability, precision and repeatability in compliance with the latest international mounting standards.

Particular attention has been paid to energy efficiency which through patented designs provides the largest energy saving solutions available in this market.

Every stage of manufacturing and product testing is carried within our specially equipped departments at our headquarters in Lurano (BG).

The worldwide presence of Pneumax ensures optimized and coordinated project management: the highest level of service is provided to all of our international customers.

Watch the video

Clamping

Clamping

Our rigid linkage prevents the unwilling clamping of two workpieces together, thus enabling the clamp to detect such anomalies in the process. Stepless adjustment with the quickest…

Keep reading View productsClamping arms

Locating

Locating

High locating accuracy. High protection against welding debris and corrosion…

Keep reading View products

Handling

Handling

Pivoting

Pivoting

Robust and reliable pivot units to accurately position and/or rotate tooling or parts to work condition…

Keep reading View products

NC Locator

NC Locator

Complementary products

Complementary products

Pneumax is a ONE-SOURCE SUPPLIER for the Automotive Industry with a comprehensive line of: pneumatic drives, valves, valve terminals, communication control blocks…

Keep reading View products

Accessories

Accessories

Fittings, sensor, tubes, auto-retaining device, EC001, shims and spacers…

Keep reading View productsProduct development

1 Concept

Market requirement evaluation and product specs definition by product management. The project team analyzes the technical feasibility and sets a general timeline.

2 Prototyping

After a structural mechanics simulation analysis, the R&D team prepares a CAD model which is used with a 3 axis printing-moulding machine to manufacture the first prototypal batches.

3 Electronics integration

Electronic components are developed and manufactured in-house by Pneumax to be integrated in any system or as interface to any protocol.

4 FMEA

The first close-to-series samples are machined, using the latest generation machinery. The first FMEA is prepared.

5 Evaluation and Inspection

Life test and approval. The products are subjected to functional, performance, temperature tests for millions of cycles.

6 Engineering

The engineering department evaluates and adopts the most suitable manufacturing technology and assembly procedure to implement, using 3D simulation programs.

7 Product industrialization

The industrialization team together with the technical department develop any specific equipment and tool required. Suppliers’ evaluation is accomplished.

8 Pilot series release and product audit

Verification and validation that the product meets the requirements.

Contact Pneumax staff about any requests or quotes.